Polyurethane (PU) foam machinery is a critical asset in industries such as automotive, furniture, construction, refrigeration, and packaging. These machines handle complex chemical reactions, precise mixing, and controlled dispensing, making proper maintenance essential for consistent foam quality, operational efficiency, and safety. Regular maintenance not only extends the lifespan of the machinery but also minimizes downtime and production losses, ensuring reliable industrial operations.

Leading suppliers of PU Foam Machinery emphasize the importance of structured maintenance programs. These programs involve routine inspections, preventive measures, timely replacement of components, and operator training. By following comprehensive maintenance guidelines, manufacturers can maximize machine performance, reduce operational costs, and maintain compliance with safety and environmental regulations.

Daily Maintenance Practices

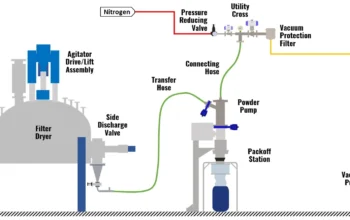

Daily maintenance is the first line of defense against equipment issues. Operators should start by inspecting key components, including pumps, mixing heads, valves, and pipelines, for visible wear, leaks, or blockages. Ensuring that raw material tanks are at the correct temperature and properly agitated is critical for smooth chemical flow and consistent foam quality.

Cleaning is also an essential part of daily maintenance. Residual chemicals can build up in mixing heads, pipes, and dispensing nozzles, potentially causing blockages or inconsistent foam properties. Using appropriate cleaning agents recommended by the manufacturer prevents contamination and reduces the risk of equipment damage. Additionally, operators should check control panels, sensors, and display units to confirm that all automated systems are functioning correctly.

Preventive Maintenance Schedules

Preventive maintenance involves scheduled inspections and servicing designed to identify and address potential problems before they cause machine failure. Key components such as pumps, motors, heaters, and mixing heads should be examined periodically for signs of wear or misalignment. Lubrication of moving parts and calibration of metering systems ensures accurate chemical ratios and consistent foam density.

Manufacturers often provide preventive maintenance schedules detailing daily, weekly, monthly, and annual tasks. Adhering to these schedules helps maintain optimal performance and prevents costly unplanned downtime. For high-volume operations, preventive maintenance is especially crucial for reducing the risk of production interruptions and maintaining high product quality.

Component Replacement and Spare Parts

Over time, certain components of PU foam machinery, such as seals, gaskets, pumps, and mixing blades, may wear out or lose efficiency. Timely replacement of these parts is essential to prevent breakdowns and maintain safe operation. Using original spare parts recommended by the manufacturer ensures compatibility and maintains the performance standards of the equipment.

Maintaining an inventory of critical spare parts allows for rapid replacement during maintenance, reducing downtime. Modern PU foam machinery often includes modular components, which can be easily swapped without major disassembly, further minimizing production interruptions.

Monitoring and Calibration

Accurate chemical metering and precise temperature control are vital for consistent foam production. Regular monitoring and calibration of metering pumps, heating systems, and pressure sensors ensure that all parameters remain within optimal ranges. Calibration routines should follow manufacturer guidelines, and records of adjustments should be maintained for quality assurance purposes.

Advanced PU foam machinery may include automated monitoring systems that alert operators to deviations in temperature, pressure, or chemical flow. These systems enhance preventive maintenance efforts by providing real-time data and identifying potential issues before they affect production.

Operator Training and Safety

Proper operator training is a critical component of PU foam machinery maintenance. Well-trained operators can identify early signs of wear, handle minor repairs, and perform routine maintenance tasks safely. Training should also cover chemical handling procedures, emergency shutdown protocols, and safety measures to minimize risks associated with high-pressure systems and reactive chemicals.

Safety features such as emergency stop buttons, pressure relief valves, and leak detection systems should be tested regularly. Operators should be familiar with these systems and conduct periodic drills to ensure readiness in case of an emergency.

Environmental and Facility Considerations

The environment in which PU foam machinery operates also affects maintenance requirements. Proper ventilation, controlled temperature, and humidity levels help maintain machine efficiency and chemical stability. Additionally, ensuring that the workspace is clean and free from debris reduces the risk of contamination and mechanical wear.

Environmental compliance should be maintained by monitoring emissions, managing chemical waste, and following local regulations for disposal. Proper facility practices complement machinery maintenance, contributing to overall operational sustainability.

Documentation and Record-Keeping

Maintaining detailed records of all maintenance activities is essential for long-term machine reliability. Documentation should include inspection logs, calibration records, component replacements, and any incidents or repairs. These records support preventive maintenance planning, quality assurance, and compliance with safety and environmental standards.

Conclusion

Effective maintenance of PU foam machinery is essential for ensuring consistent foam quality, operational efficiency, and safety in industrial production. Daily inspections, preventive maintenance, timely component replacement, calibration, operator training, and environmental considerations all contribute to the reliable performance of the machinery.

By adhering to structured maintenance guidelines and maintaining proper documentation, manufacturers can reduce downtime, minimize costs, and extend the lifespan of PU foam machinery. Investing in proper maintenance practices ensures that production remains uninterrupted, foam quality stays consistent, and operations comply with industry standards and safety regulations.