Swiss lathe machines have become an essential tool in precision manufacturing, particularly for producing small, intricate components with tight tolerances. However, not all Swiss lathes are the same, and selecting the right type is critical for meeting production needs efficiently. Understanding the differences between machine types can help manufacturers optimize workflow, quality, and cost-effectiveness.

Classic Swiss Lathes

Traditional Swiss lathes are known for their mechanical simplicity and stability. These machines typically feature a guide bushing that supports the workpiece near the cutting tool, minimizing deflection during machining. Classic Swiss lathes excel in producing long, slender components and offer high precision for small-diameter parts. While they may lack advanced automation, these machines provide reliable performance for small-batch or specialized production environments.

CNC Swiss Lathes

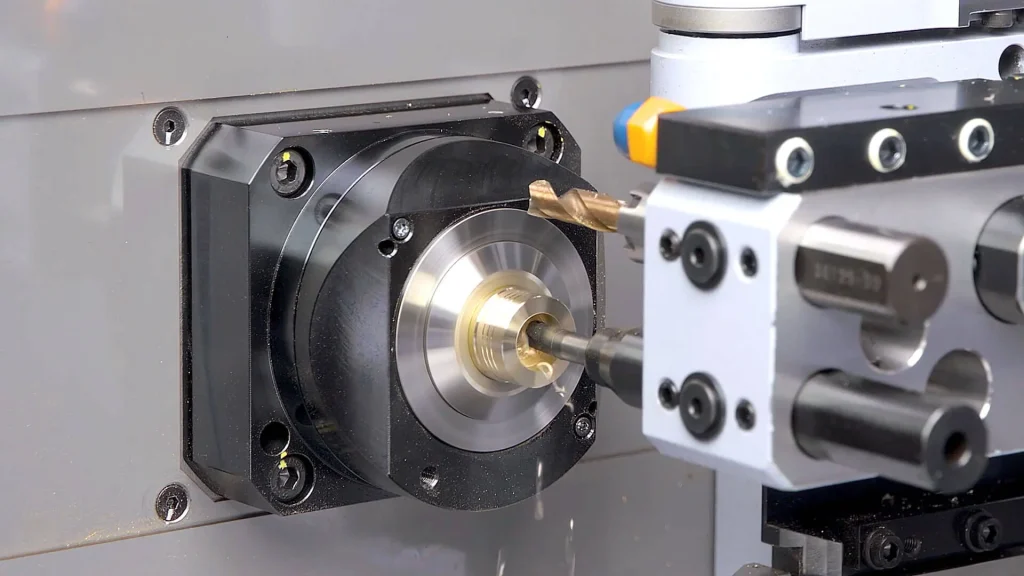

CNC-equipped Swiss lathes incorporate computer numerical control for enhanced accuracy and automation. Multi-axis CNC systems allow for simultaneous turning, milling, drilling, and threading in a single setup. These machines reduce manual intervention, improve repeatability, and accommodate complex geometries with ease. A modern swiss lathe machine often features live tooling, automated tool changers, and bar feeders, providing flexibility and efficiency for both small and high-volume production.

Sliding Headstock Swiss Lathes

Sliding headstock Swiss lathes are designed to handle long bar stock efficiently. The headstock moves in coordination with the guide bushing, maintaining continuous support for the workpiece. This configuration is ideal for producing extended components with consistent diameters and excellent surface finishes. Sliding headstock designs reduce vibration and deflection, contributing to high precision, especially when working with delicate materials or long parts.

Fixed Headstock Swiss Lathes

Fixed headstock models offer robust performance for shorter or medium-length components. These machines are simpler in design compared to sliding headstock lathes and are easier to maintain. Fixed headstock Swiss lathes often feature multi-axis CNC capabilities and live tooling, making them suitable for complex parts in small or medium batches. They balance precision and cost-effectiveness, making them a practical choice for workshops with diverse production requirements.

Multi-Axis vs. Single-Axis Machines

The number of axes is a key factor when comparing Swiss lathes. Single-axis machines perform turning operations primarily, while multi-axis models can handle simultaneous milling, drilling, and threading. Multi-axis machines are ideal for producing intricate components in a single setup, reducing cycle times and minimizing handling errors. Single-axis models may be sufficient for simpler parts, offering a lower cost without compromising basic precision requirements.

Automation and Production Volume

Automation features differentiate Swiss lathe machines in terms of production efficiency. High-volume production benefits from automatic bar feeders, tool changers, and in-process monitoring, which allow machines to operate continuously with minimal supervision. For low-volume or custom production, machines with manual setups or limited automation may be more cost-effective while still delivering precise results. Evaluating workflow requirements alongside machine capabilities helps determine the best balance between automation and operational flexibility.

Material Capabilities

Different Swiss lathes are optimized for varying materials. Machines with rigid frames, stable guide bushings, and high-speed spindles handle harder metals such as stainless steel or titanium effectively. For softer metals, plastics, or alloys, high-speed capabilities and efficient chip evacuation become more important. Understanding material compatibility ensures that the selected machine can produce consistent quality without excessive tool wear or downtime.

Maintenance and Longevity

Maintenance requirements also vary between machine types. CNC and multi-axis machines may require more specialized servicing compared to simpler fixed headstock models. Proper maintenance practices, including lubrication, calibration, and tool inspection, are essential for sustaining precision and extending machine life. Choosing a Swiss lathe that aligns with available maintenance resources helps maintain long-term operational efficiency.

Conclusion

Comparing different types of Swiss lathe machines involves evaluating factors such as headstock design, axis capabilities, automation, material handling, and maintenance requirements. Classic, sliding headstock, fixed headstock, and CNC-equipped models each have unique advantages suited to specific production scenarios. By carefully analyzing workflow needs and component complexity, manufacturers can select the most appropriate Swiss lathe machine to achieve precision, efficiency, and long-term reliability in small and intricate part production.