Modern press machine factories are increasingly integrating automation and advanced technology to enhance efficiency, precision, and safety in manufacturing processes. Press machines play a critical role in shaping, cutting, and forming metals, and their production requires meticulous attention to detail. By adopting automation, factories can reduce human error, improve production consistency, and optimize workflow, ensuring that the final machines meet the high standards demanded by industrial operations.

A Press Machine Factory leverages technology in every stage of production, from design and machining to assembly and testing. For an overview of modern industrial-grade machines and technological applications, you can visit Press Machine Factory. Automation and technology not only streamline manufacturing but also enable factories to produce highly complex and customized press machines efficiently. Understanding how technology is applied in these factories highlights the ways modern manufacturing has evolved to meet the demands of high-volume and precision-driven production.

Computer-Aided Design and Engineering

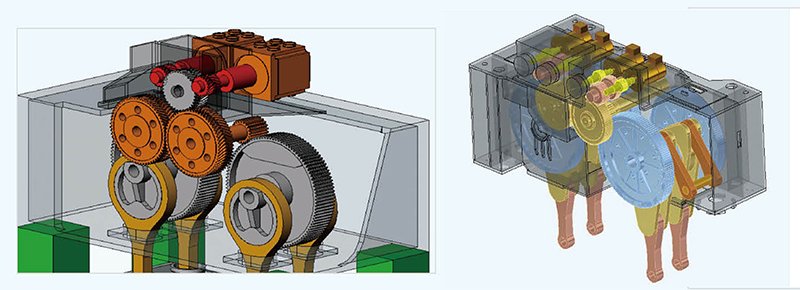

Automation begins at the design and engineering stage of press machine manufacturing. Engineers use computer-aided design (CAD) software to create detailed models of the press, including its frame, ram, drive system, and safety mechanisms. CAD allows for simulations of stress, vibration, and load distribution, enabling engineers to identify and correct potential design flaws before production begins.

Computer-aided engineering (CAE) tools further enhance design precision by analyzing how the machine will perform under various operational conditions. Finite element analysis (FEA) can simulate the effects of heavy loads on the frame and critical components, ensuring that the press machine is both durable and reliable. These technologies reduce trial-and-error in physical prototyping, saving time and resources while ensuring high-quality output.

Automation in Machining and Component Fabrication

Advanced manufacturing technology is heavily applied during the machining and fabrication of components. CNC (Computer Numerical Control) machines, robotic arms, and automated milling equipment allow for precise cutting, shaping, and drilling of metal parts. CNC machines can produce complex components consistently, maintaining tight tolerances that are essential for press machine performance.

Automation reduces the risk of human error, enhances repeatability, and increases production speed. Factories also employ automated inspection systems, such as laser measurement tools and coordinate measuring machines (CMM), to verify component dimensions and alignment in real-time. This ensures that each part meets stringent specifications before moving to the assembly stage.

Robotics and Automated Assembly

The assembly of press machines is another area where technology plays a key role. Robotic arms and automated lifting systems handle heavy components such as frames, rams, and bolsters, reducing physical strain on workers and minimizing the risk of assembly errors. Robots can also perform precise alignment tasks that are critical for ensuring smooth operation of the press.

In addition to robotic assistance, factories use automated torque tools, fixtures, and jigs to standardize assembly procedures. These tools ensure consistent fastening, alignment, and positioning of components, which directly affects the operational accuracy and longevity of the press machine.

Advanced Control Systems and Automation Integration

Modern press machines themselves are often equipped with advanced control systems, including programmable logic controllers (PLCs), human-machine interfaces (HMIs), and digital monitoring tools. Factories integrate these systems during assembly, allowing machines to operate with precision and efficiency. Automation in control systems facilitates variable stroke lengths, adjustable force settings, and programmable production cycles, making presses versatile for different manufacturing applications.

Automation also extends to integrated production lines, where press machines communicate with feeding, handling, and finishing equipment. This reduces manual intervention, increases throughput, and ensures consistent product quality.

Quality Assurance through Technology

Automation enhances quality assurance by enabling continuous monitoring and testing throughout the manufacturing process. Sensors, automated inspection tools, and data analytics allow factories to detect deviations early, ensuring that only components meeting specifications are used in assembly. Functional testing of assembled press machines is often conducted with automated equipment, simulating operational conditions to verify accuracy, safety, and performance.

Technology also facilitates traceability and documentation, with detailed digital records of component measurements, assembly processes, and testing results. This allows factories to maintain high standards and quickly address any issues that may arise.

Safety and Ergonomic Benefits

Automation in press machine factories improves workplace safety by reducing direct human interaction with heavy or high-risk components. Robotic handling, automated assembly tools, and integrated safety systems protect operators from injury. Ergonomic benefits include reduced physical strain and a safer, more controlled production environment, which contributes to both productivity and employee satisfaction.

Conclusion

Automation and technology have transformed press machine factories, enabling higher precision, efficiency, and safety in production. From computer-aided design and CNC machining to robotic assembly and advanced control systems, technology is integral to every stage of manufacturing. By integrating automation, press machine factories can produce reliable, high-quality machines while reducing errors, increasing productivity, and enhancing workplace safety. These technological advancements ensure that modern press machines meet the demanding requirements of industrial operations and provide long-term operational efficiency.