Maintaining the quality of water and other liquids is essential across various industries, including manufacturing, pharmaceuticals, food and beverage, and environmental management. Monitoring chemical properties like acidity and alkalinity is crucial for ensuring safety, compliance, and process efficiency. One of the most effective tools for achieving this is the pH sensor, which provides real-time, accurate measurements to track liquid quality and detect changes that could indicate contamination or process deviations.

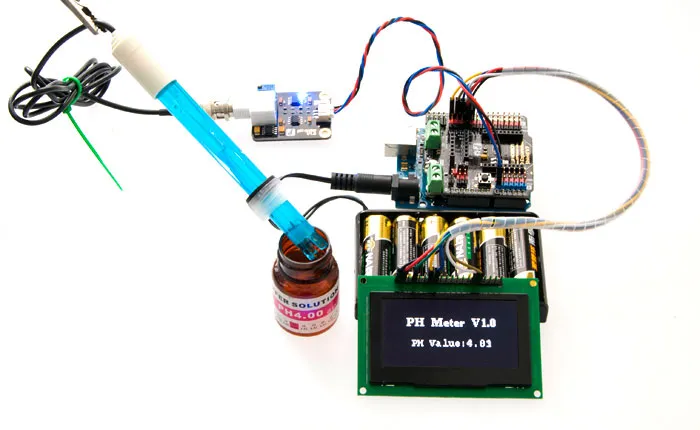

pH sensors work by measuring the concentration of hydrogen ions in a solution and converting this information into an electrical signal that indicates the pH level. These sensors are widely used to monitor water and liquid quality because of their precision, reliability, and ability to integrate with automated systems. For an in-depth explanation of how these sensors operate and their applications in industrial and environmental monitoring, you can refer to this comprehensive guide on pH sensors, which covers their technology, functions, and practical uses.

Importance of pH Monitoring in Liquid Quality

The pH level of water and other liquids can reveal a great deal about their quality. Water that is too acidic or alkaline can corrode pipes, reduce the effectiveness of chemical treatments, or create unsuitable conditions for industrial processes. Similarly, in beverages, pharmaceuticals, or chemical manufacturing, deviations in pH can indicate spoilage, contamination, or incomplete reactions. By continuously monitoring pH with pH sensors, operators can detect these changes early and take corrective action to maintain quality standards.

Types of pH Sensors for Quality Monitoring

Different types of pH sensors are used depending on the liquid type, environment, and required accuracy:

- Glass Electrode Sensors: Offer high accuracy and are ideal for aqueous solutions in laboratories and industrial applications.

- ISFET Sensors (Ion-Selective Field Effect Transistors): Solid-state sensors that provide fast response times and durability in challenging chemical conditions.

- Combination Electrodes: Integrate the measuring and reference electrodes in a single unit, simplifying installation and reducing maintenance requirements.

Selecting the appropriate sensor ensures reliable performance and consistent quality monitoring in various liquid systems.

Integration With Automated Monitoring Systems

pH sensors can be integrated into automated monitoring and control systems, enhancing their effectiveness in detecting changes in liquid quality:

- Real-Time Monitoring: Continuous pH readings allow operators to identify deviations immediately.

- Automated Adjustments: Systems can automatically add neutralizing agents, adjust processes, or trigger alarms based on sensor readings.

- Data Logging: Historical pH data enables trend analysis, quality reporting, and regulatory compliance.

- Alerts and Notifications: Immediate alerts ensure rapid response to abnormal pH levels, preventing damage, spoilage, or safety hazards.

This integration reduces the risk of human error, improves process control, and supports high standards of liquid quality management.

Maintenance and Calibration

To maintain accuracy, pH sensors require regular calibration and maintenance. Calibration involves using standard buffer solutions to correct for electrode drift and environmental factors. Routine cleaning and inspection prevent contamination or fouling that could affect readings. Properly maintained sensors ensure consistent monitoring over time, which is critical for both industrial and environmental applications.

Applications in Various Industries

pH sensors are utilized in multiple industries to detect changes in water and liquid quality:

- Water Treatment Plants: Ensuring safe pH levels for drinking water, wastewater, and effluent discharge.

- Food and Beverage Production: Monitoring acidity to maintain taste, safety, and product consistency.

- Pharmaceutical Manufacturing: Controlling solution pH during formulation and processing to safeguard drug quality.

- Chemical Industry: Maintaining optimal pH for reactions, preventing contamination, and ensuring product quality.

In each application, continuous pH monitoring allows operators to respond quickly to changes, protecting both quality and safety.

Benefits of Using pH Sensors for Quality Monitoring

Employing pH sensors to track liquid quality provides several advantages:

- High Accuracy: Ensures precise measurements and reliable detection of changes.

- Continuous Monitoring: Identifies trends and deviations in real time.

- Process Efficiency: Supports automated adjustments and reduces the need for manual sampling.

- Safety and Compliance: Helps meet regulatory requirements and maintain safe operating conditions.

- Cost Savings: Early detection of quality issues prevents waste, product loss, and equipment damage.

These benefits make pH sensors indispensable for industries that require precise liquid quality management.

Conclusion

pH sensors play a crucial role in detecting changes in water and liquid quality, providing accurate, real-time monitoring that supports process efficiency, safety, and compliance. By integrating sensors into automated systems and maintaining proper calibration, industries can ensure consistent quality, prevent contamination, and respond quickly to deviations. Leveraging pH sensors enables proactive liquid management, protecting both operational processes and end-product standards.